Scheuch has worked to create a name that is respected around the world. The innovative technologies it has developed over recent years have made it a leader in environmentally-friendly ventilation and exhaust air treatment systems for industrial applications world-wide.

Inserco has been collaborating and working with Scheuch for many years because it has found an outstanding company and a partner that provides exceptional service and technologies unique to the market. For a long time, Inserco has been working very hard to provide the best customer support and cooperation on projects throughout Latin America and parts of Asia.

Alois Scheuch founded Scheuch in 1963 in Austria. Scheuch’s work has mainly stood out for providing innovative solutions for air purification and its goal of delivering solutions for all tasks related to the wood processing industry. This includes serving the solid wood processing industry (sawmills, pallet plants and sectors related to construction) as well as to the furniture industry (carpentry and furniture manufacturers). The company has been continuously growing since its founding and recently separated its production division into the following departments:

* Wood processing industry

* Wood based panel industry (mostly ESP)

* Metal industry

* Industrial minerals industry (such as cement)

* Energy industry

Cutting-edge technology for the wood processing industry

Over the past 50 years, Scheuch’s product portfolio has been continuously expanded and strengthened by numerous brands. Today, the range of products focuses on extracting and removing dust (in sawmills, for example), conveying (low, medium and high pressure systems) and on tasks related to surface treatment (for example, crushing, pulverizing and drying).

Scheuch Ligno is the company’s department dedicated to the wood processing industry and it has 115 employees. This department specializes in manufacturing and producing machines for extraction systems and those with galvanized finishing. Initially, Scheuch Ligno was located inside the company’s facilities in Aurolzmünster, Austria. Last year, however, it was relocated to its own premises, 6 km away from the company’s headquarters.

Extraction Systems

Scheuch offers energy-saving and high performance extraction systems for managing and disposing of wood dust and other types of dust produced by wood processing machines. SEPAS-PLUS and SEGAS-PLUS are, for example, systems that carry out extracting and dedusting tasks for production machines. These systems can be adapted to suit the machine’s capacity and the quantity of materials involved.

SEPAS Plus.Energy-saving extraction systems

SEPAS-PLUS is the shavings extraction system designed by Scheuch Ligno and it guarantees a power output of 9000 m³/h and above. Its high energy efficiency makes it an exceptional system. One key feature of the system is that the extraction output can be adjusted to capacity fluctuations in a machine. SEPAS-PLUS is a particularly good choice for small and medium-sized companies that want to achieve higher levels of energy efficiency.

Key benefits of SEPAS-PLUS extraction systems

* Flexible single-pipe system that can adapt to machinery changes.

* Increased productivity thanks to the flexibility of the extraction system

* Lower production costs thanks to lower energy consumption.

* Better operational safety because the system prevents shaving deposits and ensures the fan is not a potential ignition source as it’s installed on the clean air side.

* Savings in heating costs because the system does not extract more air volume than necessary.

SEPAS Plus extraction systems facilities

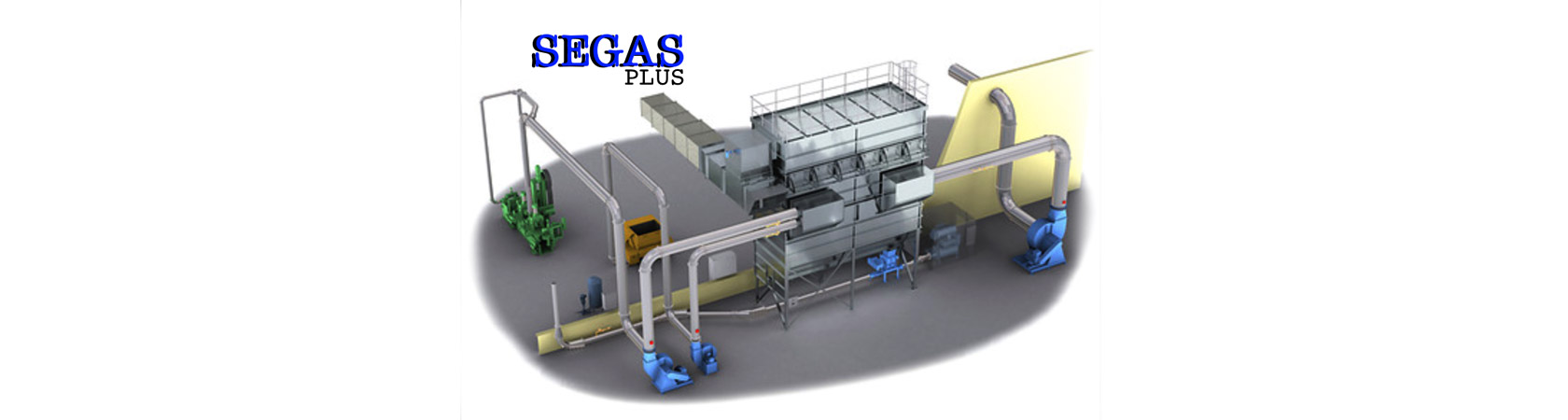

SEGAS Plus. Extraction group for maximum productivity

The extraction system SEGAS-Plus (Scheuch Effektives Gruppen Absaug System, which means Scheuch effective grouped extraction system), was built based on the know-how acquired from designing several hundred systems for the solid wood industry. These were designed as a means of maintaining consistent capacity levels in the production and manufacturing processes. The word „PLUS“ in the name represents its exceptional availability even under extreme demands – continuously running without any problems such as in multiple shifts operations. It also stands for its ability to deal with high processing speeds and extremely large amounts of dust and shavings.

SEGAS-Plus operates in continuous production, which results in machines being able to work at high capacity levels. The system’s grouping of a specific number of production machines forms an extraction group. The number of groups determines the number of fans to be installed between the extraction points and filtering system.

SEGAS Plus extraction systems facilities

PIPE SYSTEMS Wide range of pipes and duct components.

Scheuch offers a range of pipes and duct components for dust extraction, dedusting systems and pneumatic conveying systems. This allows Scheuch to meet any requirements made by its customers.

In general, Scheuch differentiates between „heavy-duty“ components made of steel or stainless steel, which are up to 6 mm thick, and „light-duty“ components, which are galvanized and up to 3 mm thick. These components were specifically designed for the wood procesing industry.

FILTERS / SEPARATORS

Scheuch offers a complete set of equipment for cleaning exhaust air and for extracting dust. This equipment, in addition to having a design that is unmatched by any other company, has evolved to be able to perform all tasks related to dedusting and cleaning exhaust air/gases.

Scheuch filter systems feature integrated pre-separation, which means optimized flow behavior (the so-called „top-down effect”). Furthermore, these machines’ soft interiors were designed to ensure an efficient and safe separation of dust particles, shavings and fibers.

LIGNO WOOD SHREDDER

Scheuch LIGNO’s quality shredder is the ideal solution for small wood processing businesses, joinery workshops, carpentries and sawmills. It comes in numerous designs and is suited for any type of application.

The LIGNO wood shredder’s strengths include following quality features:

* Reliable and profitable cutting system

* High availability and fault-free operatione

* Easy to use and intuitive control concept

* Continous and effective material infeed

* Incomparable production levels

CONVEYING SYSTEMS

The extraction, filtration and material discharge devices and conveying systems form a single unit consisting of technically advanced components with high durability. The conveying systems consist of a material unit feeder (discharging device), a conveyor and a separator at the silo or the containers.

Inserco and Scheuch both have extensive experience in taking care of their customers under all circumstances. Scheuch guarantees and assures excellent availability and operational safety for their extraction systems, unloading devices and the conveying mechanisms that are crucial in lines, such as in fan and filter systems. Scheuch has been producing rotary valves, screw conveyors, metering devices and pendulum „flaps“ for over 50 years.

Because many potential customers, in this case in Chile, knew of Scheuch’s excellent products, they were immediately interested in learning more about Scheuch Ligno, as it is a new department, different from the one they had previously worked with in the panel sector. These customers are active in the mass production sector of the timber industry.

Thanks to a major project for dust extraction at a remanufacturing plant in Concepcion, Chile, that involved a visit from Mr. Lacher, it was possible to respond to the interest of other customers and they were able to learn more about the range of products mentioned above.

Inserco would be pleased to help you learn more about the potential industry benefits of working with Scheuch systems and having clean air and a clean environment for your community.