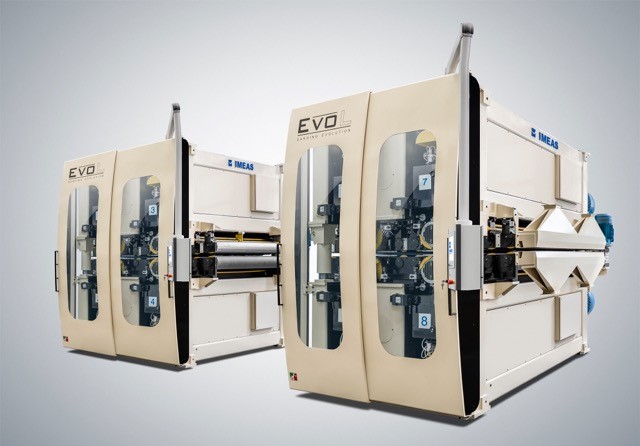

EvoL: Sanding EvoLution

IMEAS and INSERCO have been connected with each other through a strong and professional partnership for almost 25 years. Together, we are able to offer our customers a combination of a strong and local based service as well as a network of offices in most Latin American countries, by using INSERCO’s subsidiaries in Brazil, Mexico, and Colombia. Our mission is clear: to deliver a high quality product, and to offer our customers access to a full range of services to not only state-of-the-art technology but also to proven innovations and solutions such as the Sanding EvoLution EvoL.

At Ligna 2017 Imeas presented EvoL, its new line of calibrating and sanding machines for wood-based panels.

The new EvoL model represents Imeas’ ninth generation of sanding machines. As the name suggests, it is the evolution of the company’s 50-years-long experience and know-how in sanding of MDF, particleboard, plywood and others.

As a result, EvoL machines not only integrate state-of-the-art control technologies like our premium Full Control System™ and Full Control Belt™, but also simplify maintenance by reducing the number of components and improving their accessibility in all-important areas.

EvoL is a family of machines engineered to evolve continuously to face an ever challenging business and as such they offer: Excellent calibration, Superior sanded surface, Cost savings, Simplified operation, Flexibility.

What’s new?

We would like to explain to You the reason of a new feeding system:

The new feeding system is specifically designed to process also the thin boards. It’s three-stage gearbox concept leverages on fine-electronic controls to create a tension that keeps the panel flat and ease the sanding. This makes always perfect surfaces!

EvoL machines are designed for sanding speeds of up to 150m/min, with the possibility to increase up to 200m/min.

The niche products are an important key factor of Imeas success: customized products for specific needs, such as for example the line dedicated to PLYWOOD or to CLT panels.

The EvoL sanders have built-in technologies that are based on Imeas longstanding expertise and know-how in the processing of plywood panels.

This grants perfect calibration and smooth surfaces on thick panels as well as on thin panels.

The redesign has involved almost all the machine’s functional components, with the aim to reduce the mechanical complexity. As a result, the machine is now much more accessible especially for maintenance purposes. In this way our Customers can save precious time and be more productive.

Power is nothing without CONTROL!

The new version of our Full Control System™ has been reengineered together with the EvoL sanders to be fully integrated with them. It uses high-torque servomotors and enables to adjust the two sides of the sanding unit one independently from the other.

Furthermore, it can operate in conjunction with your thickness measuring system in order to make close-loop, fine adjustments.

The Imeas Full Control Belt™ tracking system is managed by an electro-pneumatic system with high performance proportional photocells which can detect the abrasive belt position.

This system is self-stable and requires no care from the operator.

As an additional feature, it is possible to set from the operator panel a controlled oscillation of the belt or to choose to fix it in the center.

That’s control!

Moreover, we are INDUSTRY 4.0 READY!

Being the next generation, Imeas’ EvoL machines fully comply with the Industry 4.0 concepts.

They can be integrated with your company’s ERP systems to exchange product information and can be controlled and managed remotely through our TeleService™ system.