Considerable cost savings, highly reliable performance, and significant reduction rejects, all these highly attractive features are united in the Sensors of Scienta. The well experienced supplier of sensors is aware of the needs of our customers and has integrated them into his development work. Simple design with the ability to integrate into lines with different setup. INSERCO is very pleased to introduce this state-of-the-art solution with its high flexibility and performance.

Who is SCIENTA?

Founded 1954, scanner production since 1974.

Strategic partners: Vits Technology, Andritz, Voith Paper,…

Scienta develops sensors and online measuring systems for the Pulp&Paper, Impregnation, and Non-woven industries.

BENEFITS to Melamine and Phenolic Resin Treater lines:

- Even resin distribution

- More productivity through automatic resin control

- Less complaints due to out-of-spec issues

- Possible cost savings due to optimized resin dosing

SCIENTA OY has over 60 years experience of suppling online measuring systems for Resin Treaters. Our references include most major companies in the market. Comprehensive set of unique sensors, scanners and software tools allow us to meet the wide-ranging demands of our customers.

VITS TECHNOLOGY GMBH as a long-term partner of Scienta is manufacturer of state-of-the-art impregnation and coating lines and is the global market leader with 1.000 lines delivered to customers.

INSERCO as partner of Scienta and Vits is your local contact and solution provider for the wood based panels and pulp industry in Latin America.

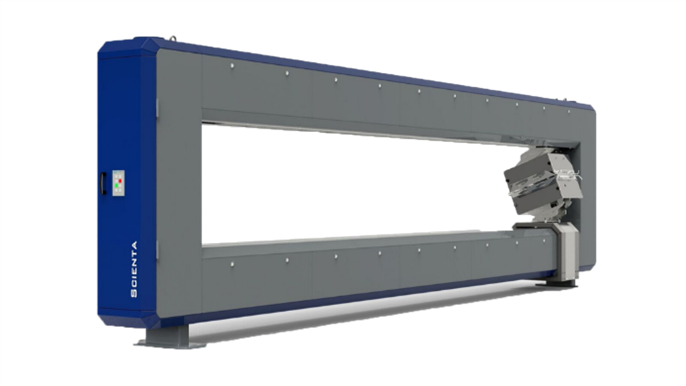

FEATURES of Scienta sensors

- Measurements: Total Weight, Resin Weight, Resin %, Volatiles, Sheet width and Sheet temperature.

- Both Wet End and Dry End scanners using new Microwave based sensors.

- Line data interface using Profinet, ControlNet, OPC and/or SQL database (reports as an option).

- Dryer temperature control + fan speed control through data acquired via Profinet/ControlNet.

- CD and MD resin amount controls are standard (based on measured dry resin %).

- Web based database reports viewable from any factory networked computer (option).

- Wide measuring range.

- Good correlation to lab results.

- Easy and convenient to install and operate.

- Capability to work with threading chains.

- Tailor made head designs for various applications.

- Reduction in rejects due to high performing measurements.

- Easy calibration and setup.

- Scanners are designed for a harsh, industrial environment with potentially high humidity and moisture levels.

- Scienta has used its extensive experience (building scanners since 1974) to produce a highly reliable and modular scanner platform.

- The scanner construction is virtually maintenance free with few regularly replaceable parts.

- Standard parts and programs are used extensively including Siemens / Allen-Bradley / ABB PLC’s. No PC is required to run the system as we can connect to most DCS systems through networks, field buses and OPC.

Double and single sided scanners, fixed point and mobile units.

Choice of control system – Siemens or Allen-Bradley.

DCS connection using Profinet, OPC and/or SQL database.

CD and MD controls are available as options.

Remote support using TeamViewer.

MATERIALS SAVINGS EXAMPLE:

- Cost of resin is approx. € 1,2 / kg (today even higher)

- Online control of resin amount will save 3-5 g/m² dry resin

- Annual savings € 88.000 – 146.000

- Increase line speed by 3-5 m/min

- Less web breaks and less scrap

We will be very pleased in cases you wish to talk about the Sienta Sensors in closer detail. Please get in touch with us!

Sincerely

Your INSERCO Team