Inserco has been specialising in the field of surface finishing for years. Whether it be engineered wood boards finished with high-quality coatings, films or decorative surfaces, metal films or sophisticated sheet metal surfaces, many products require flawless, dust-free cleaning throughout their production, often at high working speeds.

For efficient cleaning requirements such as these, our partner Wandres has developed some excellent solutions. Their activities focus on applications such as boards, sheet metal, flat glass, converting and automotive. They have the right cleaning system for every application.

Cleaning furniture boards and panels

Manufacturing steps such as sawing or edge processing produce huge quantities of particles, chips and fine dust. The product surfaces then have to completely cleaned before further processing steps commence – this is to prevent loss of quality and ensure reliable production. Smooth board and panel surfaces can be optimally cleaned with sword brushes, if necessary in conjunction with air-based cleaning systems.

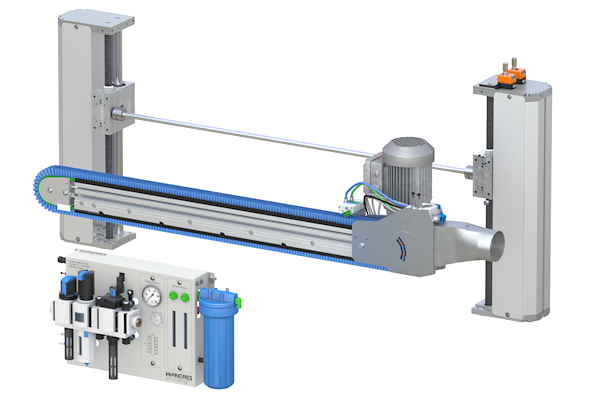

Ingromat® cleaning system

- Micro-moistening of the brush filaments with Ingromat® antistatic cleaning agent

- Product surfaces are brushed clean, particles stick to the bristles and are carried away to a suction unit

- Self-cleaning mechanism of the circulating linear brush with a rotating bristle scraper, compressed air nozzles and suction unit

Pressure buffer

The linear brush is flexibly mounted on a pressure buffer. The pressure buffer is regulated via compressed air and ensures that the brush filaments constantly assume a vertical position, therefore maintaining a constant wiping pressure even on uneven surfaces. This guarantees premium cleaning results.

Modular system

The modular system means that manufacturers can flexibly adapt the combi sword brush to the requirements of a given production line. Up to four air- or brush-based cleaning units can be combined. As such, systems can be tailored to meet specific cleaning requirements, for instance for one- or two-sided cleaning with or without air-based pre-cleaning.

We speak your language

Contact us for more information about systems from Wandres.

We are happy to help with any questions and look forward to hearing from you.

Kind regards,

INSERCO Industrie Service GmbH

Kränkelsweg 25, 41748 Viersen, Germany

Phone +49 2162 933 91-0, Fax +49 2162 933 91-33

service@inserco.de