At Inserco, we have been committed to environmental protection and recycling since day one. Whether it be recycling solid waste, utilising biomass or pellet power plants or filter systems for exhaust air and process water, we offer solutions for all of these sectors. Today, we would like to introduce you to Schrader, a technological market leader for process water treatment systems.

Schrader draws on many years of experience in process engineering and offers high-performance systems which are energy efficient, sustainable and reliable.

Process water treatment – prerequisites and aims

The manufacture of MDF boards produces waste water that is contaminated with process-specific residues and cannot be discharged via public disposal facilities.

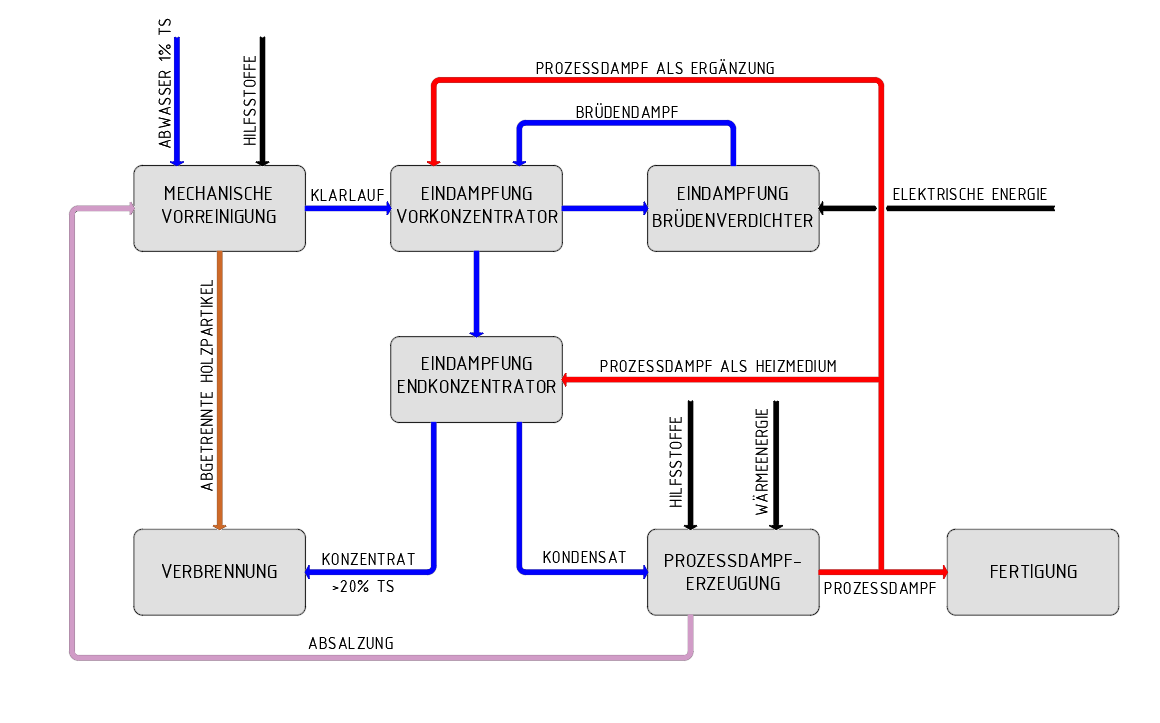

For the economic treatment of process water, Schrader developed an energy-efficient recycling system:

- Mechanical pretreatment or process water

- Evaporation of the cleaned process water

- Use of condensate for process steam generation

- Combustion of solids separated during mechanical pretreatment as well as the condensate from the evaporation

To ensure the 98% availability of this system, a continuous flow must be ensured within the system and all process data must be analysed, including the quantity, quality and temperature of the process water produced.

Short description of process steps

Mechanical pretreatment:

- Separation of > 1 mm particles from the process water

- Fine separation of impurities by means of decanter centrifuge

- Delivery of cleaned water for evaporation

- Delivery of separated solids for combustion

Evaporation:

- Concentration of process water to 30% dry matter

- Use of exhaust vapours as a heating medium through mechanical or thermal vapour compression

- Delivery of condensate for process steam generation

- Delivery of condensate for combustion

Process steam generation:

- Generation of process steam from the condensate of the evaporation system

- Delivery of process steam to the refiner of the MDF production

- Delivery of the process steam to the evaporation system

Advantages of the evaporation system

Advantages of the Schrader system:

- Downstream components protected against wear and obstruction

- Two-stage falling film evaporator as part of the CIP concept

- Minimisation of heating energy through mechanical or thermal vapour compression

- Use of energy in the condensate in steam generation

- Heat exchangers protected through natural circulation in the steam generator

Advantages of the evaporator system:

- Residue-free process, water is turned to steam, solids are transported way for combustion

- Meets all official requirements, because no waste water is delivered to public treatment facilities

- Reduces fresh water costs by 50%

- Reduces costs of boiler feedwater treatment by up to 100%

- No waste water discharge costs

- Responsible, environmentally friendly technology

We speak your language

Contact us for more information about systems from Schrader.

We are happy to help with any questions and look forward to hearing from you.

Kind regards,

INSERCO Industrie Service GmbH

Kränkelsweg 25, 41748 Viersen, Germany

Phone +49 2162 933 91-0, Fax +49 2162 933 91-33

service@inserco.de