Frequently occurring problems.

Innovative solutions.

Ness filter station FF 300 and FF 500

By: Ing. Eduardo Ruiz.

Can anyone claim that they have never had any kind of problem with the circulation of heat transfer fluid in their production machinery? Most likely not.

The proper functioning of the heat transfer fluid system in wood-based panel machines or low pressure presses is of critical importance for the productivity of the plant and the quality of the end product.

For service teams, it is always a challenging endeavour to monitor the internal condition of this system. In general, maintenance work is limited to the regular cleaning of the filter. In plants where more importance is placed on preventative measures, regular oil analyses are performed and the heat transfer fluid is changed out at the end of its service life (which doesn’t always make sense). Changing out all the fluid does of course come with considerable costs.

With regard to workplace safety, the replacement of the filter is one of the highest-risk maintenance tasks in the context of work on the heat transfer oil system. This is particularly true if the work has to be performed when the system is hot or before a safe temperature has been reached.

Problems with heat transfer, encrustation and complicated flushing and emptying processes after a filter or fluid change are things that most people presumably want to avoid at all costs.

Encrusted pipes and dirty filters. Kindly provided by Ness Wärmetechnik GmbH.

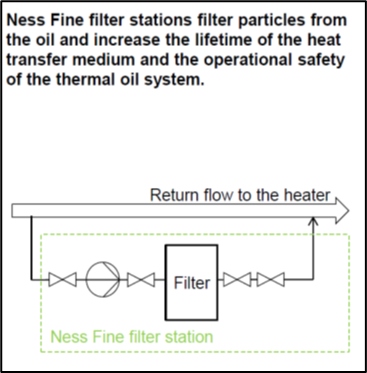

Fortunately, Ness Wärmetechnik GmbH has developed the FF 300/FF 500 filter system to make our work easier and help us minimise, and centralise, maintenance work on the system. This solution extends the service life of our heat transfer oil while at the same time guaranteeing the reliability of a controlled process with regard to the heat transfer in the press.

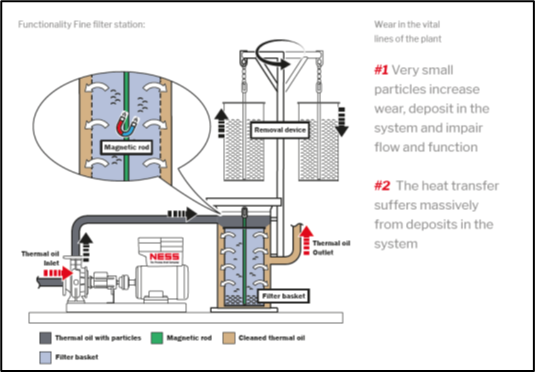

The Ness filter stations are in-line systems that work at the operating temperature of the fluid circuit, remove ferrous impurities resulting from pump and pipe wear, and keep the CCR test (Conradson carbon residue) in an appropriate range for longer, so that the fluid always remains liquid and maintains optimal heat transfer efficiency.

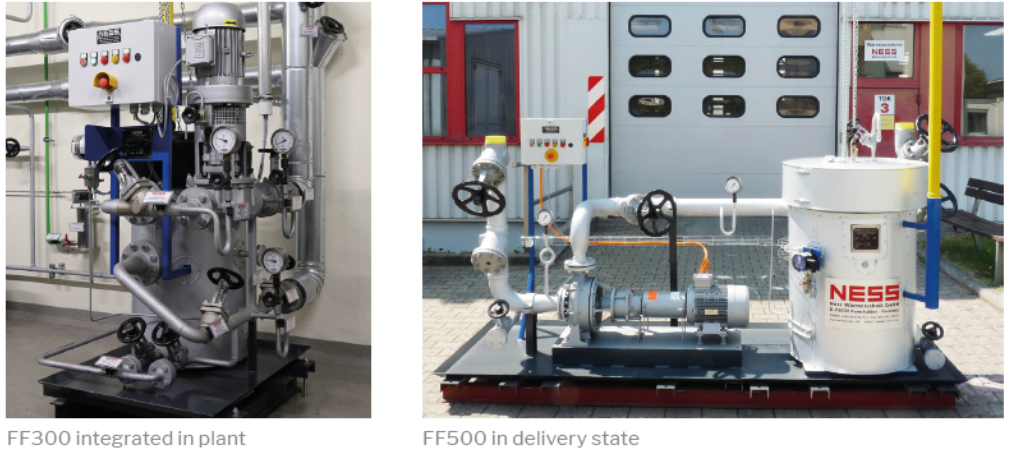

The station is fitted with an easy-to-remove, easy-to-clean cartridge as well as the required spare cartridges and accessories for easy and safe handling. It must also be emphasised that the Ness filter station does not cause any fluctuation in the flow rate or pressure of your thermal fluid circuit.

Operating schematic of the Ness filter station. Kindly provided by Ness Wärmetechnik GmbH.

It has been a pleasure to be able to present to you this solution. If you want to make your heat transfer fluid systems safer, more maintenance-friendly and more efficient, we recommend the Ness filter station. There are two different models available: FF 300 for circuits with a volume of up to 80,000 litres and FF 500 for circuits with a volume of up to 250,000 litres. In terms of filter fabric, there are different mesh types available that determine the degree of purity and the maintenance friendliness.

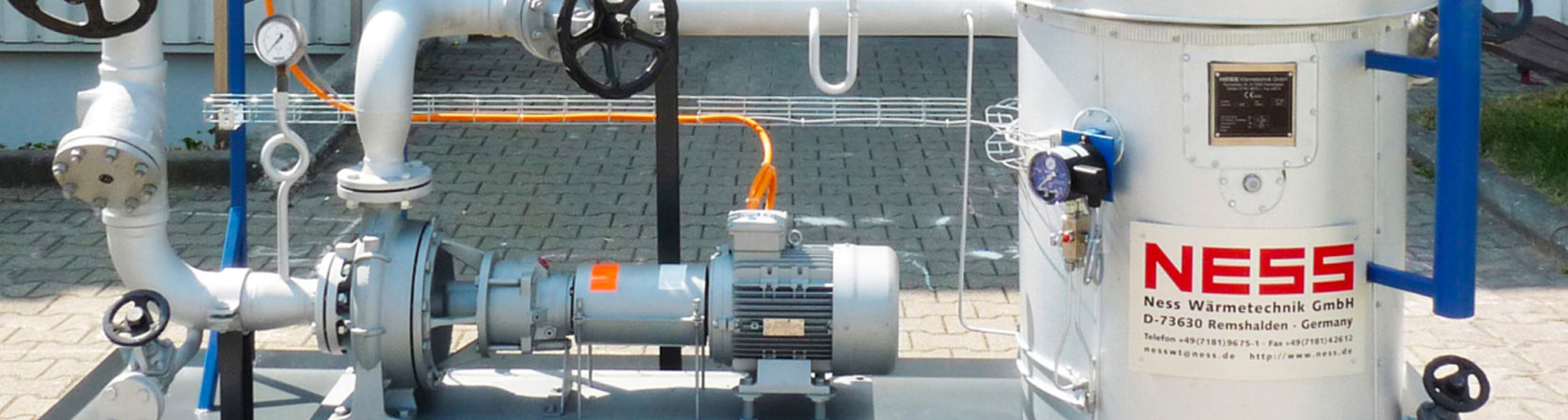

Kindly provided by Ness Wärmetechnik GmbH.

I hope that this information has been helpful for you. Thank you for reading. If you have any questions or require any additional information, don’t hesitate to contact us.

Eduardo Ruiz.

Inserco Industrie Service GmbH.