DIEFFENBACHER – 3-D feeding of knife ring flakers

B. MAIER Zerkleinerungstechnik GmbH, the company of Dieffenbacher Group, presents innovation for optimizing flake preparation

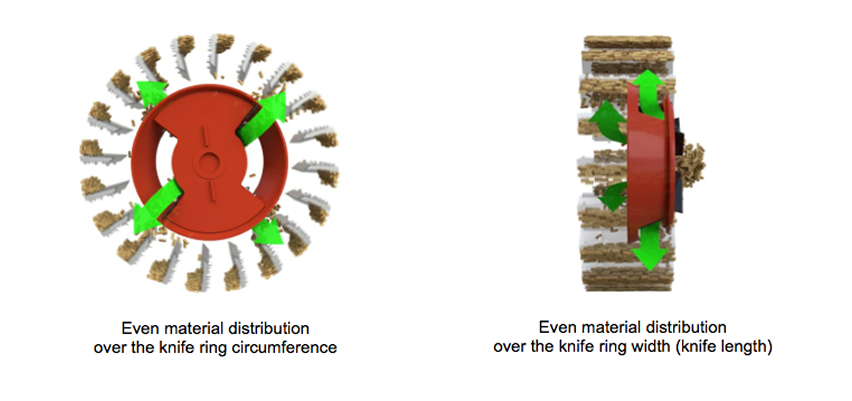

Inhomogeneous material distribution is a well-known problem of all knife ring flakers currently on the market. The material often impacts the knives of the knife ring only at a relatively limited zone. As a result, the entire knife length (knife ring width) cannot always be used evenly. Furthermore, gravity makes it impossible to distribute material over the knife ring circumference homogeneously. Consequences are uneven wear, difficulties adjusting knife protrusion, rapid worsening of the cutting conditions, and finally, loss of flake quality.

The new FlowOptimizer solves the material distribution problem and ensures optimized flake quality while simultaneously reducing operating costs per ton of material produced. The FlowOptimizer is a special distribution rotor integrated into the flaking chamber, enabling 3-D material distribution. The axially blown-in chips enter the inner chambers of the distribution rotor, are set into rotation and are guided via centrifugal forces through the openings at the front and rear side of the system toward the main rotor. This achieves optimum distribution over both the knife ring width and the entire knife ring circumference, allowing the optimum and uniform use of the entire knife length.

FlowOptimizer working principle:

Based on successful laboratory tests, a pilot machine was installed in a particleboard plant to test long-term operation under industrial conditions. Comprehensive laboratory tests clearly demonstrated that the material distribution in the flaking chamber could be substantially enhanced. Additional machines will be equipped with FlowOptimizer technology.

The new FlowOptimizer is mounted with bearings in the flaker door, making the retrofitting of existing machines very simple: Only the door with the distribution rotor and heavy particle separator must be replaced. The FlowOptimizer will be available as an upgrade for existing flaker systems and as a standard component for the latest generation of Maier MRZ knife ring flakers.

MAIER Knife ring flaker MRZ with FlowOptimizer