Inserco would like to introduce an important development in the impregnation process made by our cooperation partner Vits Technology GmbH.

In order to optimize the dryer energy consumption of the impregnation lines and to improve the production process control, reproducibility and automation of the line, Vits Technology GmbH has developed a new smart dryer concept (DRY-IT), that allows:

- Reduction of energy requirement for the drying of melamine films of up to 30%

- Start of digital process data collection and analysis (DTC | Industry 4.0)

- Improvement of the production by reproducible process control

Our solution: Control of the dryer-air-management by application of smart sensor technology for volume flow, moisture and web temperature

Total Drying Control for Your Production

Automatic control of exhaust air and supply air quantities by active moisture measurement. Control and supervision of the circulating air temperature and circulating fan speed of the dryer fields by contact-free web temperature measurement.

Version 1 – EFFICIENCY Dryer

- Exhaust air volume for current production is controlled via target value of moisture → energy consumption is decreased

- Web temperature curve is measured, monitored and documented → no over-drying of paper

- All air volumes are measured and balanced → underpressure in dryer is permanently monitored

- Interruption of production automatically results in stand-by operation → minimum energy consumption

Version 2 – SMART Dryer

- All advantages of version 1

- Each section is an independent, intelligent unit → regulation of temperature, moisture, circulating air volume

- SMART for transparent production, total process control and quality monitoring

- Moisture curve is measured, monitored and adapted to the present production

→ reproducible drying behaviour

→ adjustable to different product groups

→ no exceeding of circulating air moisture

Quick conversion to new production parameters with active splice tracking

Moisture profile of circulating air (g H2O/kg air)

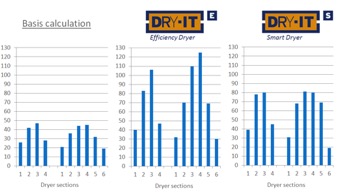

This graphic shows, that for the same product the humidity in the dryer fields (g H2O/kg air) can be increased and controlled by active moisture measurement and a good quality product is still obtained.

This means, that less air is extracted from the system, resulting in significant energy savings.

In addition, the process can be monitored and reproduced for better production control.

This system is available for new lines and can also be retrofitted to all current Vits impregnating and coating machines.

We are happy to look at your specific situation and calculate this new technology with the experts from Vits for you.

For further information, please contact us by email: