History:

In 2010, Inserco started the cooperation with Hülsemann, to introduce a new system to its customers that would revolutionize the replacement of the graphite strips which are installed in more or less every sanding machine.

Hülsemann is a German company, which was founded more than 30 years ago and is still, like Inserco, a family-owned company.

In 2004, Mr. Hülsemann himself developed the system, which makes it possible to replace the graphite strips within seconds. For this reason they are these days the leading manufacturer in this field.

Well known grinding machine manufacturers tried to copy this system, but without the same excellent quality. For 10 years Hülsemann has been producing exclusively for Steinemann.

Until today, Inserco und Hülsemann have been able to place orders in almost every Latin American country and also in Asia.

Sliding Liner System:

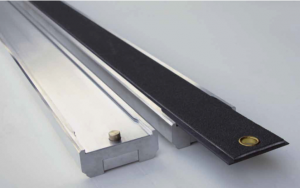

The system has been developed specially for the industrial sanding industry and consists of two parts, one is the aluminum beam and the other one are the graphite liner which are available in different hardnesses.

Aluminium beam:

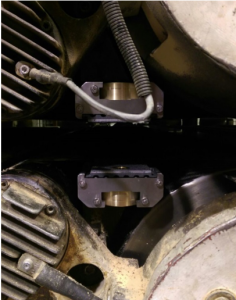

The beam is permanently installed between the relevant grinding heads of the machine. It doesn’t matter which sanding machine is in operation (Imeas, Steinemann, etc.). Hülsemann is able to manufacture nearly every customized product needed for the customer’s application. Thanks to the interaction of sleeve and pin, the liner can be exchanged in a few seconds.

Graphite Liners:

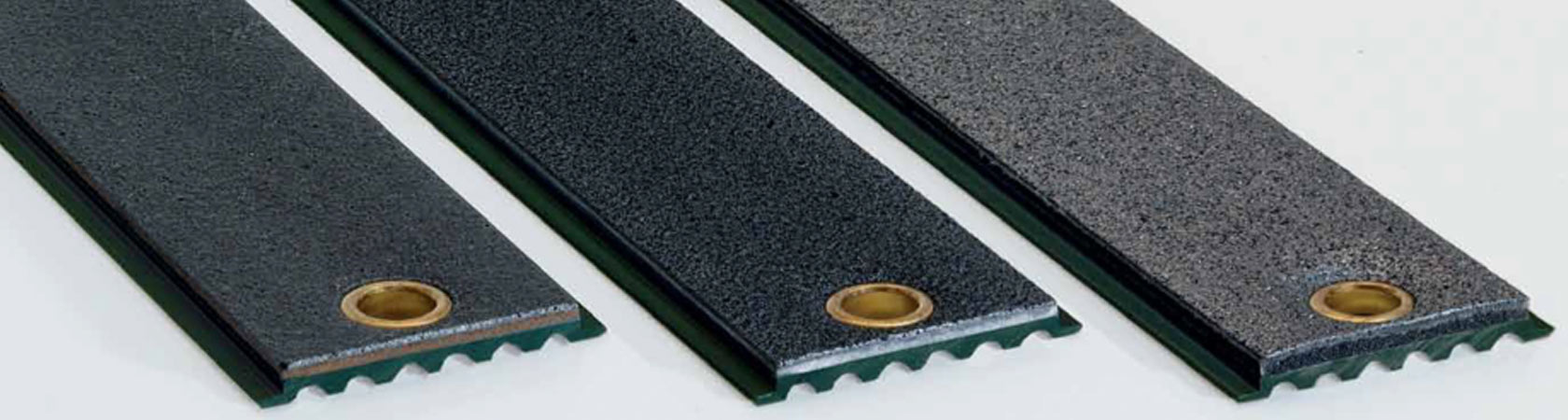

The liners are made of a heatproof plastic with special laminated padding materials. Different hardnesses are available. Customers can use the Hülsemann liner in all pad-systems. The bottom is grooved to provide a better air circulation, by this way the liners cannot overheat.

Standard slide width of 40 mm and 55 mm, total width 83 mm, length up to 3500 mm

The following types are available:

LATEX (hard, density of 055, Material: rubber, hardened polyester fleece)

PES (medium, density of 040, Material: polyester-needle-felt)

FOAM (soft, density of 015, Material: polyurethane, recompressed)

Still many companies are working with the outdated and no longer economic system, where a base is wrapped with felt and a graphite tape.

The client who will work with the Sliding Liner System can look forward to the following advantages compared to other systems:

- Ultra-fast exchange.

- Ergonomic handling / Aluminum-Beam remains in the machine.

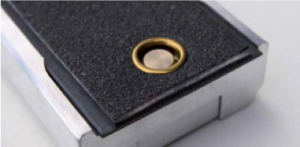

- Metal eyelet ensures discharge of electrostatic charge

- Very accurate plane-parallel contact surface (no deformation by screws).

- No slippage of padding materials possible.

- Multiple uses possible, even with frequent sanding widths.

- Material savings as a positive side effect

References:

- Glunz

- Kronospan

- Homanit

- Arauco

- Masisa

- Bischweier

- and many more

At INSERCO, we will gladly provide you with more information about devices that improve your production. If you are interested in sanding belt, Inserco could also provide you updated information about the new development of Hermes sanding belts. You can ask us!

For further information, please contact us by email: