Dear Customers and Business friends!

There are some companies that have been with us since INSERCO was founded in 1984. IMEAS from Italy is one of them. They have been with us for many years both good and critical times and have helped us to achieve the company status we have today. But also, we have been privileged to see the constant development of their products over the years, resulting in their newest EvoL line.

As the name suggests, EvoL is the evolution of more than 50 years of experience and know-how in calibrating and sanding wood panels; a year after from its launch in the market, EVOL was able to get a high appreciation in the market with more than 100 sanding and calibrating heads purchased among IMEAS customers all over the world.

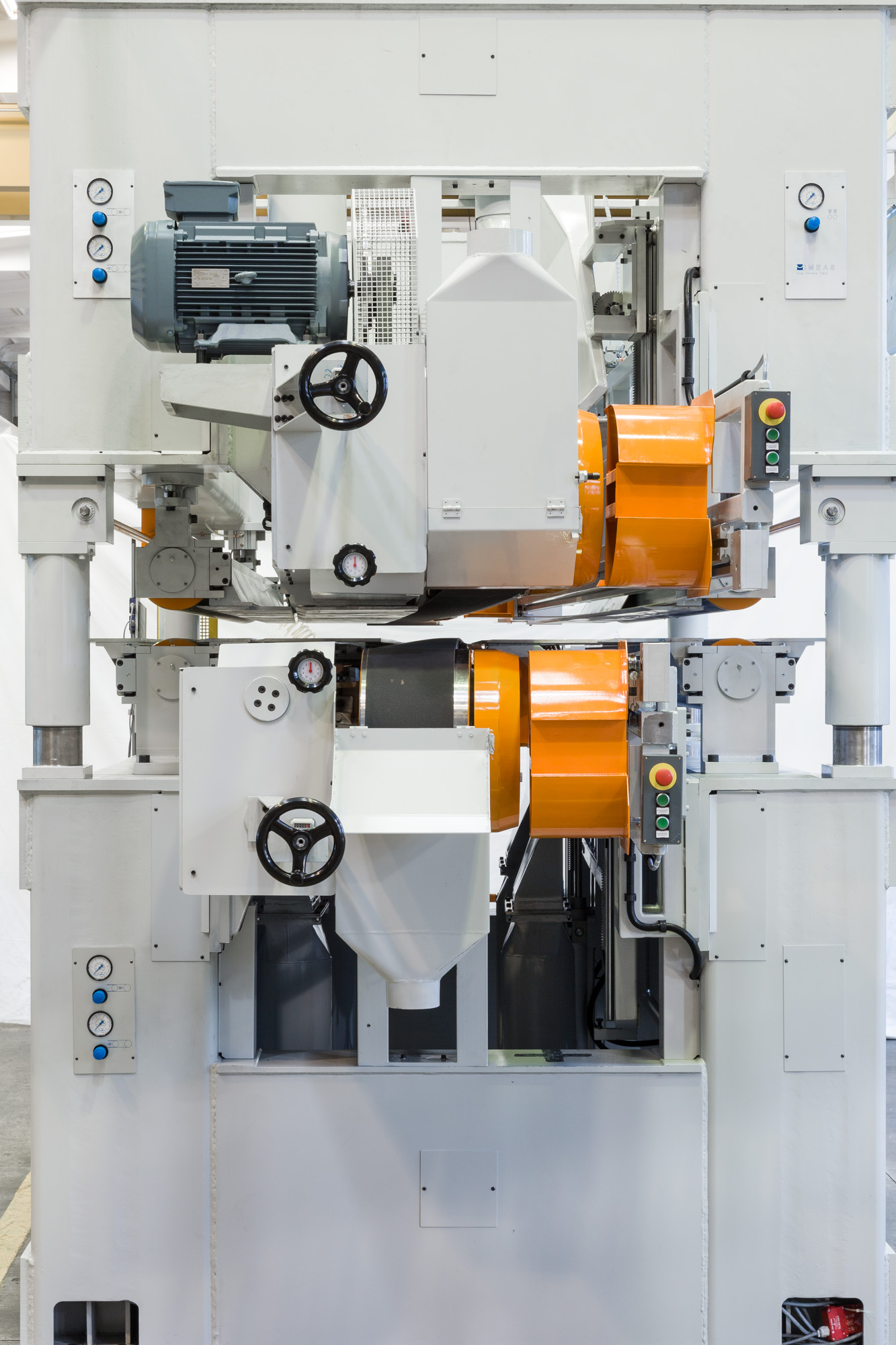

But calibrating and sanding is not an easy task. The greatest satisfaction is when a customer touches a sanded panel with his hand and remains pleased with the high quality of the finishing. This can only be achieved by having the highest quality standards and constant innovating process. All of us know the two main processes that a sanding line carries out: calibration and sanding. But IMEAS made a step further to get even smoother surfaces introducing the CR-TB model, i.e. the Cross Belt Sander.

The Cross Belt Sander is to be considered a review of the industrial sanding technique, redefining the quality and productivity factors of a modern sanding line.

This innovative solution was born with the aim to satisfy the market’s need to integrate value-added processes in the new or existing sanding lines to improve surface quality.

It is especially suitable for the production of MDF, HDF or chipboard panels intended for painting or coating with melamine papers.

With subsequent application of paints the fibers don’t straighten up again and the surface remains smooth.

The benefits are many and are both technical and environmental:

- Remove marks and lines

- Reduce the surface roughness up to 30% less than the traditional sanders

- Reduce the quantity of paint or solvents with a favorable impact on production costs.

- Improve the environmental impact

Industry 4.0 is, of course, one of the strengths of IMEAS that allows connecting all machines with each other, having feedback from the line and using this data to constantly improve the quality of the product to satisfy the customer. Along with this evolution stands out the will to improve the operability of the machine. User-friendly interfaces with touch screens and intuitive menu navigation are becoming a standard now. Changing product recipes with a few clicks and keeping the down time during product change as low as possible.

With the easiness of a click, it is possible to control every aspect of the sanding process:

- Start/Stop of the line or a single unit

- Fine tuning of the sanding unit

- Oscillation of the abrasive belt

- Auto adjustment of the eccentrics

- Operative trend monitoring

- Bearing vibration monitoring

- Alarms

The sanding recipes are designed to implement automatic adjustment and to warn operators when certain conditions happen.

The use of recipes makes it easy to create, store and recall customized working configurations of the sanding line according to the actual job.

The system can exchange data with the ERP system for a self-configuration and quality control.

If required, the recipes can also take into account the number of panels processed in each batch to adjust the position of the eccentrics to compensate automatically the consumption of abrasive belts.

IMEAS has always worked cooperating with its customers so that the engineering and technological development could be customized and could respect the needs of each customer and with the increasingly demanding market trends.

With more than 1600 processing line installed worldwide, seat in Europe, America, Asia and Oceania and constantly growing its global turnover, IMEAS is a world leader in the supply of special machines and plants for the grinding and finishing of stainless-steel metals, wood, plastic and composed materials.

It´s been over 36 years now and we hope there will be many more fruitful years of collaboration. IMEAS and INSERCO have renewed their contract again and we are looking into a bright future full of challenges and new innovations. INSERCO is proud to be the representative for such an esteemed family-owned company.

Please feel free to contact us for any need or request. It will be our pleasure to provide you with adequate assistance.

Sincerely yours,

Tim Battke

INSERCO Industrie Service GmbH

Kränkelsweg 25, D-41748 Viersen, Germany

Tel.: +49 2162 93391 32

E-Mail: tim.battke@inserco.de

Web: www.inserco.de

We speak your language

Please feel free to contact us if you wish to have more information on this or any of our large portfolio products for the general Industry. We are at your disposal for any needs and questions and are looking forward to hearing from you soon.

Kind regards

HEADQUARTER

INSERCO Industrie Service GmbH

Kränkelsweg 25, 41748 Viersen, Germany

Tel. +49 2162 933 91-0, Fax +49 2162 933 91-33

service@inserco.de

INSERCO Brasil Serviços Industriais Ltda.

Rua Cyro Correira Pereira, 667-CIC, Prédio 1-C

Bairro CIC/Cond. Empresarial Linha Verde PR 81.170-230 / Brazil

Tel. +55 41 3044 14 62

service@inserco.com.br

INSERCO Chile

Calle Avenida Nueva Alemana 155,

Pedro de Valdivia, Concepción,

Región del Bio Bio, Chile

Tel. +56 9892 268 15

arturo.riedel@insercoservice.cl

INSERCO Colombia

Carrera 67 # 169A-82, Torre 1, Apartamento 1404

Portales del norte, Suba,

111156 Bogotá, Colombia

Tel. +571 9306 427, Cel. +57 3045 3460 677

eduardo.ruiz@insercoservice.co

INSERCO México

Priv. Cromo 112, Fracc. Real de Villas,

Durango Dgo. – Mexico

Tel. +52 6188 1789 51

Cel. +521 6181 3427 15

josef.zucker@inserco.de